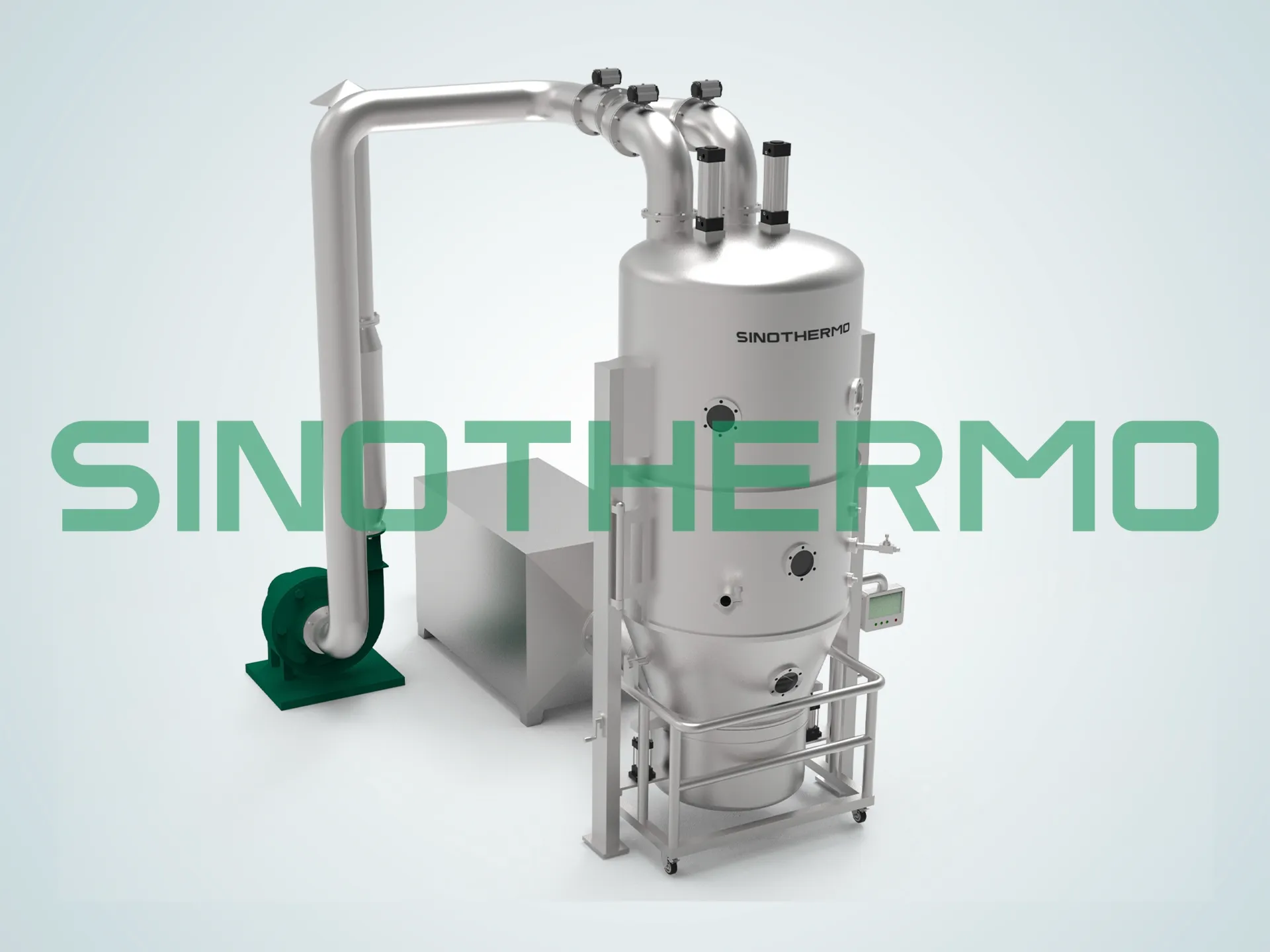

FL-Fluidized Bed Granulator

All-in-One Mixing, Granulating, and Drying:

Materials form a fluidized bed below, where granules are created in the granulation chamber with the help of spray nozzles dispensing binders. The hopper allows for the addition of multiple raw materials, which are mixed during the fluidization process.

Input: Main ingredient as powder, adhesive in liquid form

Output: Solid medium-sized granules with 3%-5% moisture content

Type: Spray Fluidized Bed, Wet Granulation

Additional Feature: Mixing, Drying, Cooling

Vertical High-Precision Granulation Technology

The Vertical Fluidized Bed Spray Granulator combines fluidized bed and spray granulation technology, offering an efficient, uniform granulation process. Especially suitable for applications requiring precise control of particle size and moisture content, such as in pharmaceutical and food processing. Its efficient design reduces energy consumption while ensuring high product quality and consistency.

- Combines fluidized bed with spray granulation

- Precise control of particle size and moisture

- Reduces energy consumption and production costs

- High output with precise particle size control

- Adapts to a variety of material needs

Applications

Chemical

Used for rapid granulation of chemical raw materials, optimizing handling and storage of chemical products.

Agriculture

Produces uniform fertilizer granules, enhancing fertilizer efficacy and crop absorption rate.

Cosmetics

Used for uniform granulation of cosmetic ingredients, maintaining product quality and consistency.

Animal Feed

Suitable for manufacturing animal feed pellets, ensuring uniformity and nutritional value of the feed.

Food

Suitable for granulating food additives and nutritional supplements, ensuring the stability and longevity of food ingredients.

Services

- Pre-Sales Testing and Experiment

- Professional Customization Design

- On-site Installation and Commissioning

- Training and Technical Support

- Full Life Circle Maintenance and After-sales

Related products