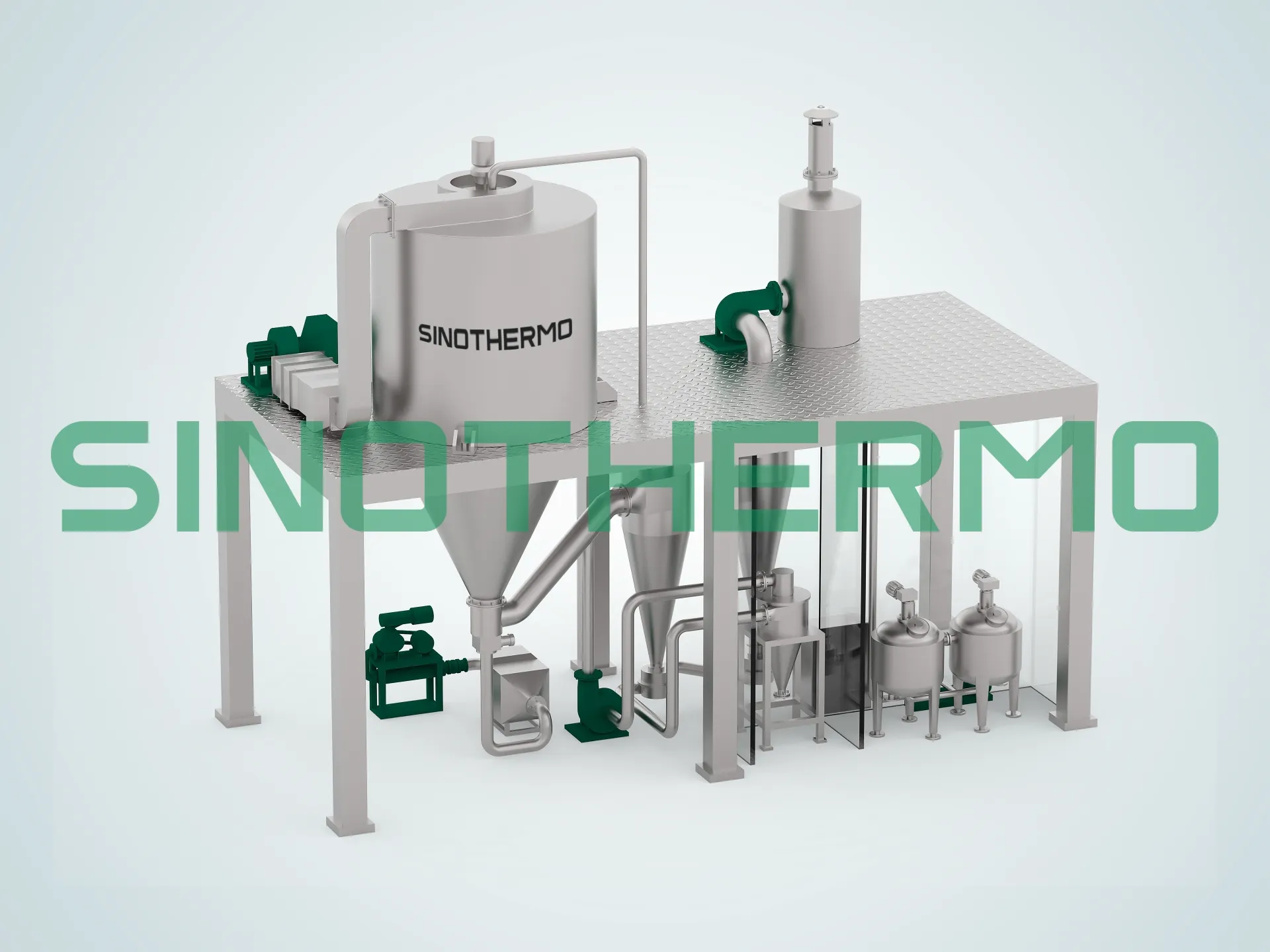

LPG-Centrifugal Spray Dryer

Advanced Liquid-to-Powder Process:

At the heart of our process, a high-speed centrifugal atomizer at the tower's peak transforms materials into super fine liquid drops. These liquid drops dry quickly upon contact with hot air, making the centrifugal spray dryer perfect for precise particle size, moisture, density and shape standards.

Input: Solutions, Emulsions, Suspensions

Output: Powder with 3%-5% moisture content

Temperature: Inlet air temperature range of 150°C to 500°

Efficient Spray Drying with Centrifugal Technology

The Centrifugal Spray Dryer provides drying and precise control, for a variety of materials including those to heat. Its advanced technology enhances efficiency, quality and maintains consistency. By regulating temperature and flow rates it produces high quality spray dried powder efficiently reduces energy consumption and caters to multiple industries.

- Swift drying technology ensures production of spray dried powder reducing processing time significantly.

- Precise management of temperature. Flow in spray drying delivers accuracy for optimal outcomes.

- Ideal for heat materials preserving integrity and quality throughout the drying process.

- Greatly improves production efficiency allowing for turnaround times and reduced operational expenses.

- Guarantees the quality and consistency of spray dryer products consistently meeting industry standards.

Applications

Food

The Centrifugal Spray Dryer is perfect for drying food ingredients like milk powder while maintaining their value and flavor.

Chemical

Efficiently dries chemicals to ensure the safety and quality of chemical products using spray drying technology.

Biotechnology

Utilizes spray drying for drying bioproducts such as enzymes and proteins to maintain their activity.

Ceramic

Perfect, for drying ceramic powders to enhance the quality of finished products through innovative spray drying techniques.

Environment

Using spray drying equipment to sludge and treat wastewater helps decrease waste volume and enhance processing efficiency.

Cosmetics

High-speed drying of cosmetic ingredients, like powders and extracts, ensuring product quality with spray drying.

Agriculture

Centrifugal spray dryers are employed for drying items, like grains and plant extracts maintaining their innate features.

Services

- Pre-Sales Testing and Experiment

- Professional Customization Design

- On-site Installation and Commissioning

- Training and Technical Support

- Full Life Circle Maintenance and After-sales

Related products