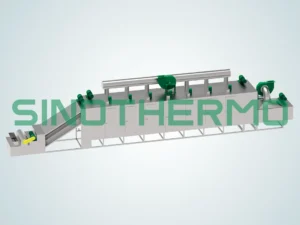

流動床造粒機: 強力な造粒機

造粒は多くの産業において重要なプロセスであり、さまざまな用途で顆粒の形成が求められます。顆粒には、流動性の向上、粉塵の減少、溶解性の向上、有効成分の放出制御などの利点があります。人気があり効率的な方法の1つは、 造粒機 製薬、化学、食品業界で使用されている最も一般的な方法は流動床造粒機です。このブログ記事では、流動床造粒の動作原理、利点、用途、考慮事項について説明します。

流動床造粒機の動作原理:

の 流動層造粒機 流動化原理に基づいて、造粒液を固体粒子(通常は粉末または細粒)の層に噴霧します。造粒液は、目的に応じて、結合剤溶液、懸濁液、または溶融物になります。流動化プロセスでは、ガス(通常は空気)を制御された速度で粒子層に通過させます。これにより、粒子が浮遊し、流体のような動作を示す流体のような状態が作成されます。

流動床造粒の利点:

Uniform Granule Formation: The fluidization process ensures uniform distribution of the granulation liquid, leading to consistent and uniform granule formation. This results in uniform drug content and improved product quality.

Controlled Particle Size: By adjusting the process parameters such as inlet air velocity, bed temperature, and spray rate, it is possible to control the particle size of the granules produced. This allows for tailored granule characteristics to meet specific formulation requirements.

Enhanced Mixing and Drying: The fluidization action promotes efficient mixing of the solid particles and facilitates rapid drying. The continuous movement of particles minimizes the risk of agglomeration and ensures efficient moisture removal.

Efficient Process Automation: Advanced process control systems often equip Fluid Bed Granulators, allowing precise control and automation of various parameters. This ensures consistent product quality, reduces operator intervention, and improves process efficiency.

流動床造粒の用途:

Fluid Bed Granulators find extensive use in various industries for the production of granules with desired properties. Some key applications include:

Pharmaceutical Industry: Fluid Bed Granulation is a key method in making and developing drug formulas. It works well for making granules used in tablets, capsules, and slow-release medicines.

Chemical Industry: The production of granular fertilizers, catalysts, detergents, and other chemical products utilizes the Fluid Bed Granulation process. It enables the incorporation of additives, improves flowability, and enhances product stability.

Food Industry: The food industry employs Fluid Bed Granulations to produce granules for instant beverages, seasonings, and food additives. The process ensures uniform distribution of flavors, improves dissolution, and enhances product texture.

流動床造粒に関する考慮事項:

While Fluid Bed Granulation offers numerous benefits, there are a few considerations to keep in mind:

Material Compatibility: It is important to ensure that the material being granulated is compatible with the granulation liquid and process conditions. Some materials may be sensitive to heat or moisture, requiring careful selection of process parameters.

Equipment Design: Proper equipment design, including the selection of appropriate nozzle types, spray patterns, and air distribution systems, is crucial for achieving desired granule properties and process efficiency.

Scale-up Considerations: When scaling up from lab-scale to production-scale, adjustments may be necessary to maintain the desired granulation characteristics. Factors such as bed height, air velocity, and drying time may need to be optimized.

結論

結論として、 流動層造粒機 is a powerful and versatile machine for granulation in various industries. The Fluid Bed Granulation process is great for making uniform granules, controlling size, and mixing and drying efficiently. This makes it perfect for use in the pharmaceutical, chemical, and food sectors. Yet, it’s important to think about whether the materials will work well with the equipment, the design of the equipment, and how to scale up the process. By getting a good grasp of how fluidized bed granulators work, their advantages, uses, and important factors to consider, businesses can make better choices and improve their granulation process for better quality and efficiency.

Remember to consult with experts and manufacturers to select the right fluid bed granulator for your specific requirements. With proper understanding and utilization, this granulating machine can significantly enhance the productivity and quality of your granulation processes.

RETCLプロセスについて:

RETCL Processは、中国江蘇省常州市に拠点を置く工業用乾燥ソリューションのリーディングプロバイダーです。技術革新、品質、顧客満足への強いコミットメントにより、RETCL Processは、様々な業界のお客様のユニークなニーズを満たすカスタマイズされた乾燥ソリューションを幅広く提供しています。

顧客体験の向上と業務の効率化に情熱を注ぐマークは、強力な人間関係の構築、イノベーションの促進、チームを率いて卓越したサービスと効率性の実現に注力している。

Eメール メール: mark.gu@sinothermo.com

電話 +86 18021972660