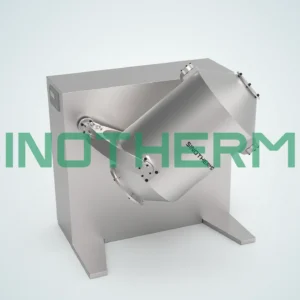

DSH-Conical Screw Mixer

Complex Motion by Dual Rotating Screws:

Move around creating a spiral motion that lifts materials from the bottom of the cone and allows them to fall naturally due, to gravity. The addition of spray atomization and jacket heating or cooling increases its flexibility.

Input: Solids, Powders, Granules, Liquids

Type: Dry Mixing, Wet Mixing

Additional Feature: Humidifying, Drying, Cooling

Innovative and Efficient Conical Screw Mixer Solution

The Conical Screw Mixer provides mixing, precise material handling for a wide range of materials ensuring consistent blending reducing energy usage and boosting productivity.

- With its twin screw design the mixer greatly enhances blending efficiency.

- It offers material handling that can be adapted to applications.

- This blender features energy-saving and cost-effective operation.

- The Conical Screw Mixer can be customized to meet blending needs.

- It guarantees mixing playing a role, in enhancing the final products quality.

Applications

Food

The mixer is also employed in blending food ingredients and additives to ensure food quality consistency.

Chemical

Additionally, it is suitable for combining raw materials and powders for product consistency.

Agriculture

The Conical Screw Mixer finds application in fertilizers to enhance fertilizer efficiency and crop absorption rate.

Animal Feed

In animal feed production, for uniformly blending grains and additives to maintain nutritional balance.

Services

- Pre-Sales Testing and Experiment

- Professional Customization Design

- On-site Installation and Commissioning

- Training and Technical Support

- Full Life Circle Maintenance and After-sales

Related products