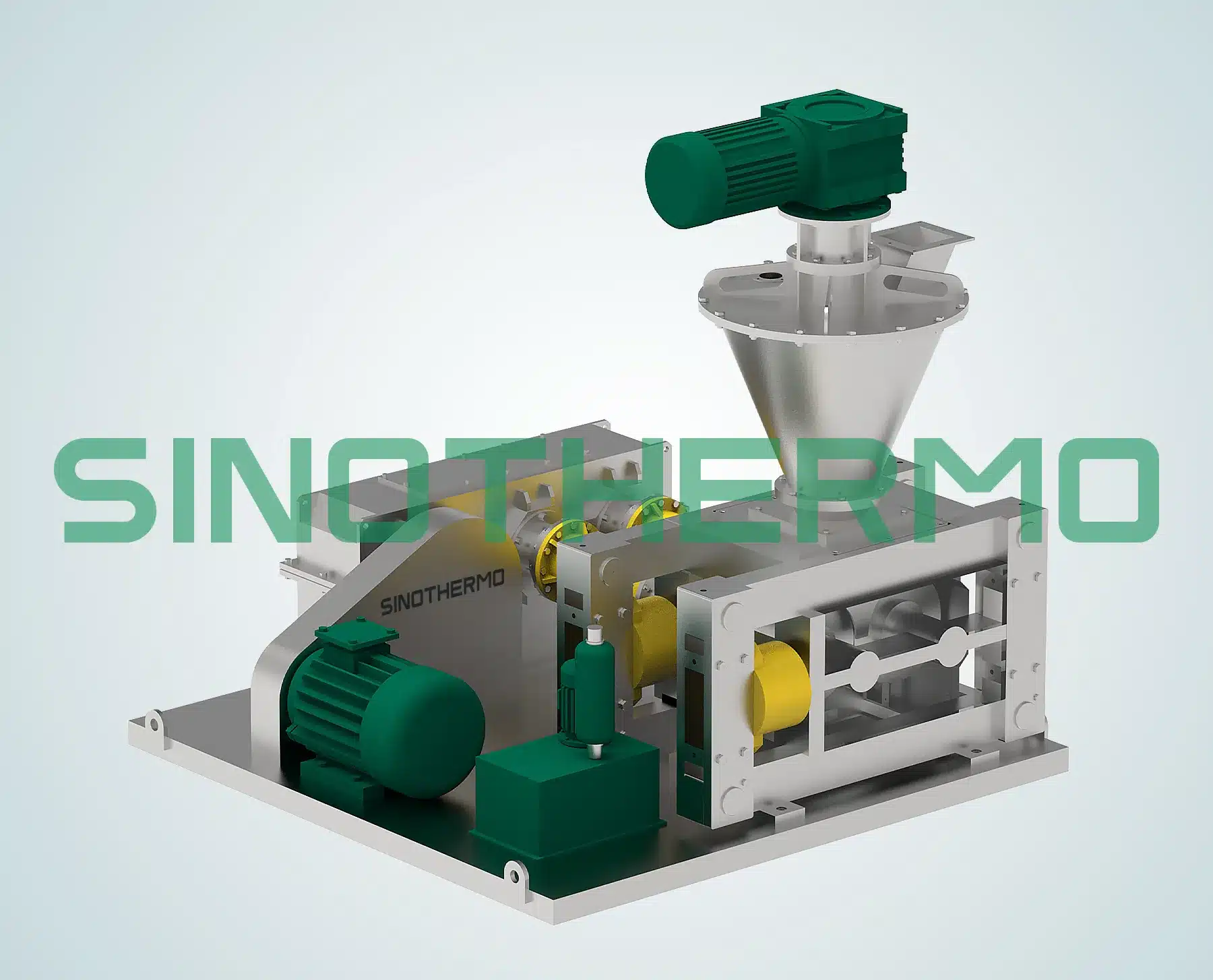

GKDH-Dry Compression Granulator

Additive Free Dry Granulation Process:

Dry raw materials are compressed under pressure to form solid flakes. These flakes are then. Processed into the desired granules.

Input: Powder

Output: Solid Granules

Type: Dry Granulation

Additional Feature: Crushing, Screening

Efficient and Reliable Dry Granulation Technology

The Dry Granulation operates without the need, for any liquid during the granulation process. This equipment not eliminates the necessity for drying steps but minimizes material wastage. Its effective performance guarantees uniformity and stability in particle formation making it well suited for applications, in the pharmaceutical, food and chemical sectors.

- Dry granulator without the addition of liquid simplifies production, saves steps.

- The granulation results in consistent and stable product quality enhancement.

- Operating the granulation process is straightforward cost effective.

- It offers particle sizes to cater to production needs effectively.

- Supports a flexible granulation process that easily adapts to different needs, ensuring high-quality results.

Applications

Animal Feed

Ensure the nutritional balance and stability of feed and enhance animal digestion and absorption.

Food

Dry granulation can be used for food raw materials such as milk powder and condiments to improve the mixability and fluidity of the product.

Mining

Compress powdery minerals into particles to reduce dust and improve mineral processing efficiency.

Environment

Used for environmentally friendly materials such as recycled plastics and biomass fuels to improve material processing efficiency and application performance.

Services

- Pre-Sales Testing and Experiment

- Professional Customization Design

- On-site Installation and Commissioning

- Training and Technical Support

- Full Life Circle Maintenance and After-sales

Related products