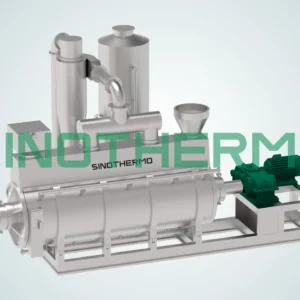

DZLG-Ribbon Conical Vacuum Dryer

Conical Vacuum Dryer with Hollow Ribbon Technology:

With its jacket and ribbon design the Conical Vacuum Dryer provides a heating surface, efficient material loading and smooth discharge without any dead angles. The ribbon facilitates mixing for heating and blending processes. This dryer is perfect for operating under low temperature vacuum conditions making it suitable, for handling explosive and heat sensitive materials.

Input: Loose powdery, granular solids

Output: Powder with 3%-5% moisture content

Temperature: Heat source temperature <200°C

Additional Feature: Stirring and mixing

Conical Vacuum Dryer Pioneers Versatile Drying Technology

The Conical Vacuum Dryer merges cone design with spiral mixing technology to achieve effective and consistent drying. Specifically tailored for agglomerating or adhesive materials it facilitates low temperature drying within a vacuum setting safeguarding materials from heat damage while maximizing energy efficiency improving production output and elevating product quality.

- The advanced design of the cone and spiral mixing mechanism enhances the blending efficiency.

- Designed for agglomerating or sticky substances to ensure processing in the conical dryer.

- Enables temperature drying within a vacuum environment leading to energy savings in the Nauta dryer.

- This design optimizes energy usage while enhancing drying effectiveness.

- It significantly enhances product quality and consistency.

Applications

Food

The dryer is used for drying food additives and nutritional components, safeguarding food quality and safety.

Chemical

Efficiently processes chemical raw materials and fine chemicals, the Nauta Dryer boosts product stability and quality.

Biotechnology

Ideal for drying enzymes and proteins, preserving biological activity with the gentle processing of this dryer.

Agriculture

Enhances storage stability and processing efficiency for seeds and agricultural by-products.

Plastics

This dryer prevents the degradation of plastic particles and rubber materials.

Ceramic

The dryer ensures the quality and consistency of ceramic powders and materials.

Services

- Pre-Sales Testing and Experiment

- Professional Customization Design

- On-site Installation and Commissioning

- Training and Technical Support

- Full Life Circle Maintenance and After-sales

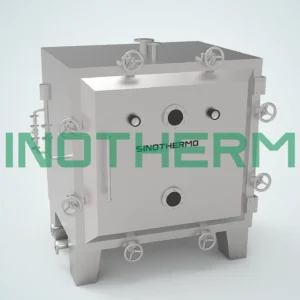

Related products