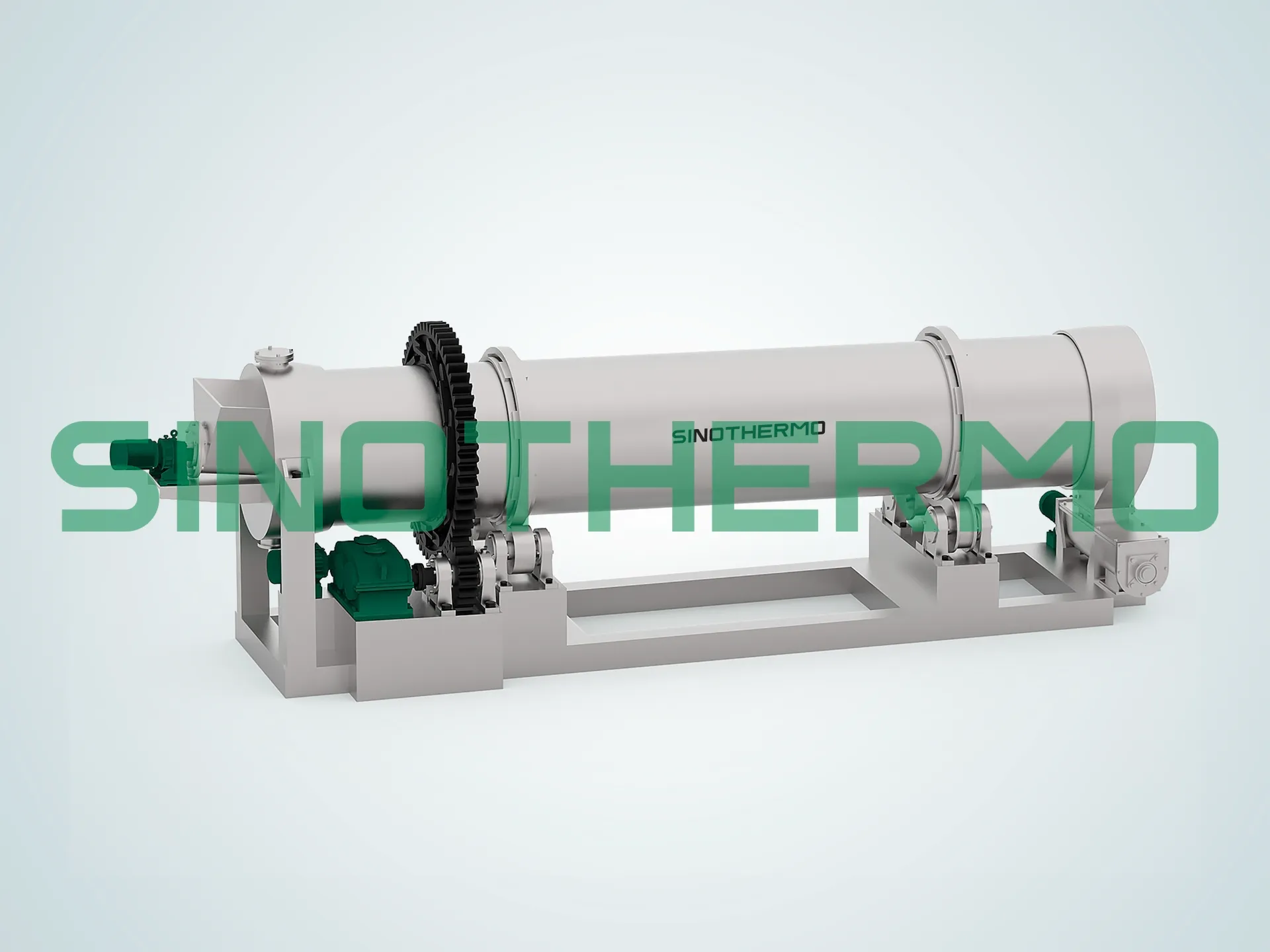

HZG-Rotary Kiln

Perfect for Scale Ongoing Drying in the Rotary Kiln: Beginning at one end of the Rotary Kiln wet materials. Are agitated by internal flights blending thoroughly with hot air. This elongated Drum dryer, spanning meters processes hundreds of tons, per hour. The Drum speeds can be adjusted from 1 to 10 RPM to suit requirements. Input: Granular materials Output: Granules with 3%-5% moisture content Temperature: Inlet air temperature range of 40°C to 350°C Additional Feature: Mixing

Efficient and Versatile Rotary Drying Solution

The Rotary Kiln is well known for its heat transfer and consistent drying performance making it ideal, for handling quantities of materials. With temperature control and adjustable rotation speed it ensures drying and material stability while also cutting down on energy usage providing a cost efficient drying option for users.

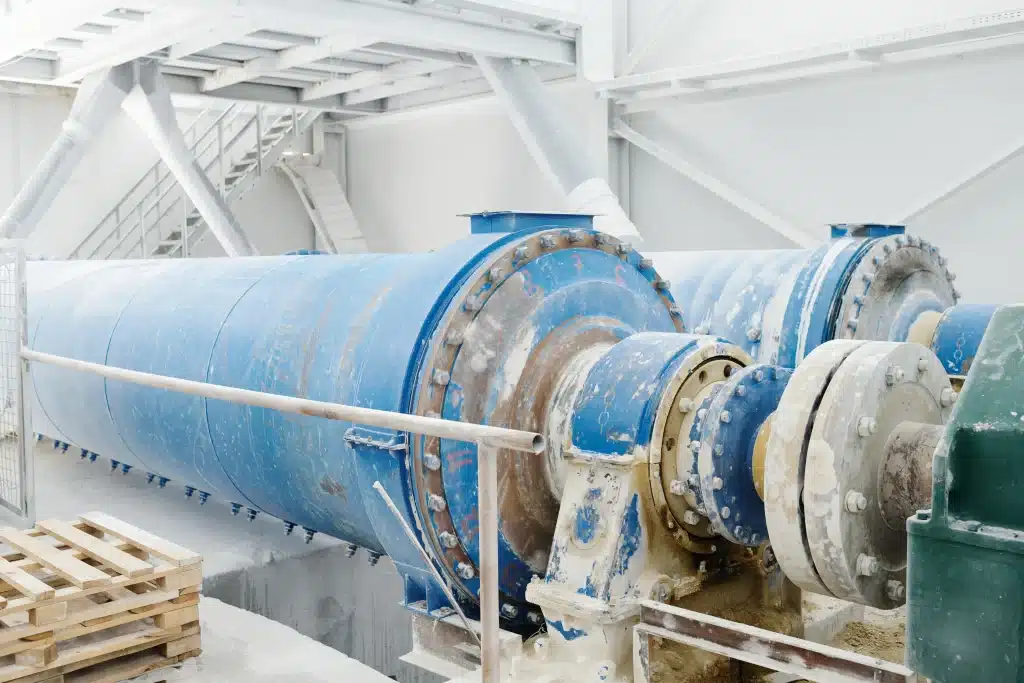

- The Rotary kiln technology efficiently transfers heat resulting in energy savings.

- It boasts a capacity effectively handling types of materials.

- This system offers controlled heating allowing for adjustments to ensure stable and uniform drying.

- The Drum dryers design emphasizes friendliness by reducing emissions.

- It has proven reliability over extended periods, designed to withstand the test of time.

Applications

Construction

It is suitable for drying cement, lime and other construction materials to enhance their strength and stability.

Agriculture

This equipment is used for drying grains and crops to preserve their quality and storage durability in agriculture.

-scaled-e1705026228938.webp)

Food

Ideal for drying food ingredients like grains, vegetables and fruits to retain their nutrients and flavors.

Mining

Effective in the drying of ores and minerals to improve processing efficiency and product quality.

Wood

Suitable for use, in wood chips or wood drying processes to enhance wood quality and usability.

Textiles

The dryer is effective, in ensuring that fabrics like cotton and wool are dried thoroughly and with quality.

Services

- Pre-Sales Testing and Experiment

- Professional Customization Design

- On-site Installation and Commissioning

- Training and Technical Support

- Full Life Circle Maintenance and After-sales

Related products