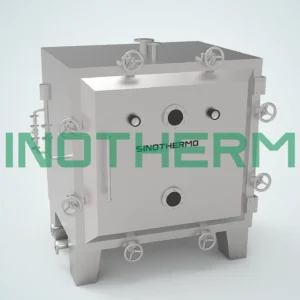

PLG-Vacuum Vertical Plate Dryer

Effective Continuous Vacuum Conduction Dryer:

The Vacuum Plate Dryer incorporates discs for efficient heating providing a generous heating surface in a compact layout. It excels in vacuum operations at temperatures making it ideal for managing flammable, explosive and heat sensitive materials.

Input: Loose powder, Granules

Output: Powder, Granules with 3%-8% moisture content

Temperature: Heat source temperature <200°C

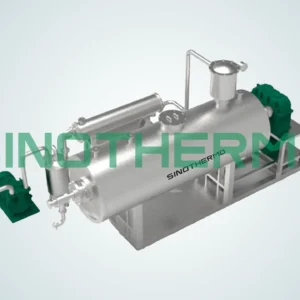

Versatile Giant in Plate Dryer Technology

The Plate Dryer enhances drying effectiveness through its continuous drying method and multi layer plate design. It is designed for scale drying, saving energy and protecting delicate materials by operating at lower temperatures. This method reduces heat loss enhances product quality and provides efficiency advantages.

- Utilizing plate drying technology for efficient and even drying across all materials.

- Well suited for large scale processing with the Turbo Dryer ensuring outcomes for materials.

- Operating at temperatures to protect heat materials from harm.

- Significantly reducing heat loss to improve the quality of dried products.

- Featuring an automated system that boosts production efficiency in Continuous Plate Dryer operations.

Applications

-scaled-e1705026228938.webp)

Food

Ideal for food ingredients and additives this dryer maintains nutrition and flavor highlighting the versatility of the Vacuum Plate Dryer.

Environment

Effectively dries waste and recycled materials enhancing material recovery and efficient utilization.

Agriculture

Efficiently dries products such, as grains, fruits and vegetables to enhance storage and processing quality.

Ceramic

Ideal, for the drying of powders and granules to maintain the high quality of the final products.

Mining

Ensures product purity showcasing a significant advantage of dryer technology.

Services

- Pre-Sales Testing and Experiment

- Professional Customization Design

- On-site Installation and Commissioning

- Training and Technical Support

- Full Life Circle Maintenance and After-sales

Related products