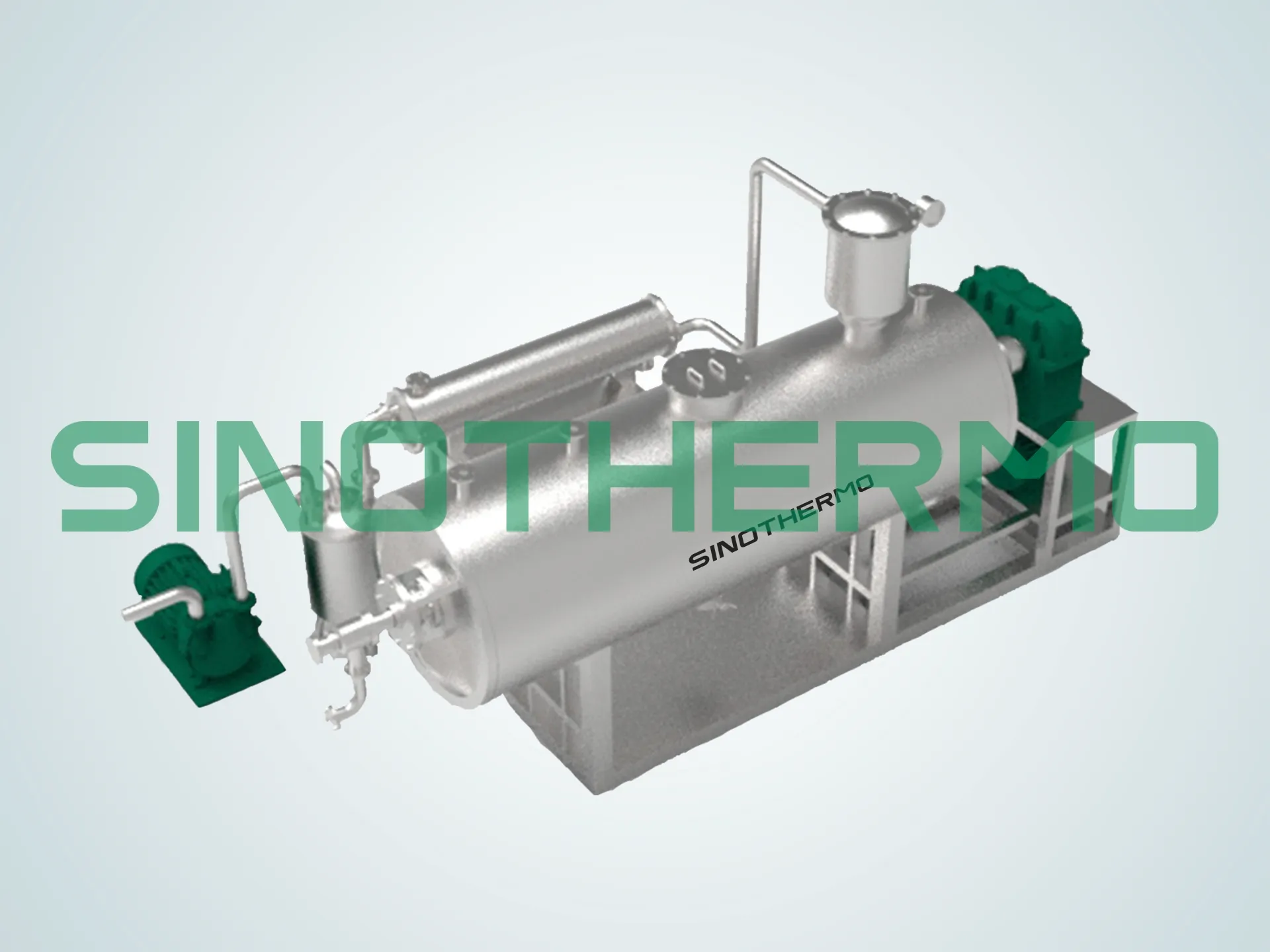

ZPG-Vacuum Rake Dryer

Rake Agitator Vacuum Conduction Dryer:

The Rake Dryer comes with a large area jacket heating system and a rake agitator that increases the heating surface area making it easier to move and heat materials. It can operate at temperatures under vacuum conditions making it perfect, for handling flammable, organic solvent and heat sensitive materials.

Input: Liquids, Slurries, Pastes, Mashes

Output: Powder with 3%-10% moisture content

Temperature: Heat source temperature range of 50°C to 200°C

Additional Feature: Stirring, Mild Crushing

Innovative Multifunctional Vacuum Rake Drying Expert

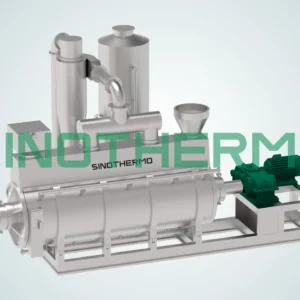

The Rake Dryer utilizes a rake style mixing technique to dry various materials in a vacuum setting. This method is especially beneficial for materials to heat or oxidation allowing for quick drying at temperatures while maintaining material quality and purity. The rake design enhances drying effectiveness reduces drying time and decreases energy consumption providing users with a cost efficient drying option.

- By incorporating rake style mixing the Rake Dryer ensures heating, throughout the materials.

- The Vacuum rake dryer excels in gentle drying at temperatures optimizing energy usage.

- It is perfectly suited for heat easily oxidizable materials safeguarding their integrity.

- This technology upholds the quality and purity of the materials delivering drying results.

- The dryer significantly boosts drying speed and operational efficiency.

Applications

Food

Using the vacuum rake dryer for food ingredients and additives helps maintain their value and flavor.

Biotechnology

For substances, like enzymes and cell cultures it offers a gentle yet effective drying process.

Environment

Employing the Rake Dryer to dry waste and environmental materials greatly enhances waste treatment efficiency.

Agriculture

The dryer is especially useful, for drying crops and agricultural by products which helps improve their longevity and quality.

Mining

When used for drying ores and other minerals the dryer significantly boosts the efficiency of mineral processing operations.

Services

- Pre-Sales Testing and Experiment

- Professional Customization Design

- On-site Installation and Commissioning

- Training and Technical Support

- Full Life Circle Maintenance and After-sales

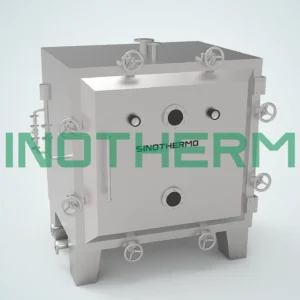

Related products